New Cannabis Sample Preparation Solutions: Monitoring the Plant and the Product

The cannabis industry is expanding to include a widening range of extracts and products

Along with this diversity comes a greater need for cannabis sample analysis tools to monitor both the plant and the product. Analysis of genetics, cannabinoid potency, and the absence of elevated contaminants are absolutely essential in ensuring cannabis is of the highest quality and is safe for consumers.

Sample preparation plays a prominent role analytical lab testing. Whether testing cannabis plants in the field or cannabis products and extracts in the lab, quality testing depends on high-performance sample preparation solutions.

Monitoring the Plant

At the plant level, cannabis is challenged by inherent inconsistency making routine and reliable analyses of cannabis crops tedious. A history of selective breeding and disparities in genetic and chemical classification have led to considerable potency and genetic variation among plant types. This variability is compounded by the influences of environmental factors on cannabinoid production.

Lower production costs and higher yields are drivers for the industry overall. Diversification of the industry to include “craft” plant types in addition to wholesale product, however, has necessitated methods for increased strain selectivity, consistency, and quality control.

Field Sampling for Cannabis Quality Control

Cannabis cultivators have increasingly turned to plant sampling technologies for on-site testing to ensure consistency in cannabis and legal hemp crops. There is, however, a lack of plant sampling tools with which to quickly acquire material from the field and effectively transport samples to the analytical lab for genotype verification, microbial contamination, or other testing.

- The Mini Leaf Crusher from BioSpec Products is an innovative solution that uses a relatively simple but effective sampling technique. By the use of a high-pressure clamp, plant samples are crushed and released extract is immediately captured and stabilized on specialized cellulose filter paper. Multiple samples can be processed at once without the need for preservative or temperature control. Using published methods, nucleic acids (DNA/RNA) can be released from the substrate and purified for downstream use with number of commercial kits available for genetic screening and genotyping, testing for pathogenic Aspergillus sp, and other applications.

Monitoring the Product

Although a range of cannabis grinding solutions are available, there is a general lack of basic, low-cost tools available to perform routine plant or product sample preparation in the lab. The use of such tools can be advantageous for routine analysis of: plant cultivation conditions, soil quality, fertilizers, pest control, and other environmental factors. These tools can also be valuable for optimizing extraction methods at lab-scale, prior to scale-up to production. Product safety is another key area that benefits from these tools, to ensure end-products of safe for consumption and investments of time and money are well-spent.

BioSpec Products offers a series of solutions to address these needs.

Quick and Efficient Sample Preparation

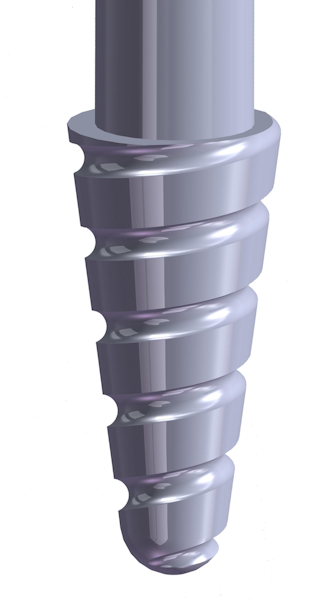

- The SpiralPestle and MicroTube Homogenizer is an ideal low-cost solution for preparation of small samples and softer materials such as cannabis flower. The unique screw-like pattern on the pestle surface channels the material, suspended in extraction solution, to the bottom of the vessel where it is macerated and mechanically dispersed. Grinding is further enhanced by the inclusion of a small amount of glass grinding beads. The action can either be performed manually, or optimized by the use the hand-held BioVortexer for increased efficiency and throughput.

- The Cryo-Cup Grinder (CCG) is another low-cost solution designed to manually pulverize fresh or frozen cannabis samples while preserving labile intracellular biochemicals. Emulating a classic mortar and pestle in design, the CCG has been optimized for grinding tissue at extremely low temperatures in the presence of dry ice (-78 °C) or liquid nitrogen (-196 °C). Called “cryo-grinding”, the extreme cold makes fresh plant tissue brittle and easy to fragment. The coolants are then removed by sublimation, leaving a finely powdered product ready for subsequent solvent extraction. Compared to traditional mortar-pestles, the CCG provides superior results.

Multiplex and Multi-Scale Sample Preparation

- The BioCryo Tissue Grinder is a high-speed blade mill designed for grinding or shredding plant materials in preparation of extraction in water- or solvent-based solutions. Up to 10 grams of dry material can be processed in under one minute, producing a shredded, granular, or powder-like consistency, depending on duration. Further extraction in the BioCryo Tissue Grinder with a variety of solutions enables enrichment for cannabinoids, terpenes, and flavonoids for biochemical analysis or plant chemotyping.

- The BioHomogenizer and TissueTearor are a solution for sample preparation and extraction of heat-sensitive biochemicals. Unlike many mechanical disruption methods, these hand-held rotor-stator devices generate very little heat during sample homogenization. As such, the devices are ideal for isolation of compounds such as the acid precursor forms of THC and CBD, tetrahydrocannabinolic acid and (THCA) Cannabidiolic Acid (CBDA), native plant compounds with potentially unique bioactive properties.

- Beadbeater Cell Disruptors use well-validated technology first introduced to the laboratory by BioSpec Products in 1979. Beadbeaters are machines designed to violently shake or agitate small glass, ceramic or steel beads placed inside microtubes or vials containing extraction media and plant sample. The colliding beads disrupt the tissue sample cells in minutes. Four models of Beadbeaters are offered, each optimized for different sample sizes and vial capacities, enabling the ideal solution for any cannabis processing application.

- The new SoniBeast™ (shown) uses patent-pending bead mixing technology, delivering up to 10 times faster operation when compared with conventional bead-mill cell disruptors. The capacity is twelve 0.6-mL microtubes or three 2-mL microvials per device.

- The new MBB1-Plus device can process one 2-mL microvial per run, while the MBB-16, MBB-24 are devices capable of processing batches of up to 16 or 24 microvials and have 2- and 7-mL multi-vial capacities.

- The versatile, high-throughput MBB-96 can process 96-well microplates, a rack of 45-microvials, or a rack holding two 50 mL screw-cap tubes. Depending on tube size or microplate capacity, the disruptors accommodates samples ranging from a few milligrams to 10 g (wet weight).

Summary

Variations in cannabinoid potency between crop batches and between plant types present ongoing cultivation issues. As such, efforts to verify plant genetics, optimize cannabis yields, and enhance quality control require reliable testing and sampling strategies. The identification and accurate measurement of potency, pesticides, and other contaminants in cannabis extracts and products is of crucial importance as well.

New sample preparation technologies are evolving to address these current challenges – offering state-of-the art solutions for cannabis testing, from the field to the lab.

This editorial was written by LabX and published in collaboration with BioSpec Products