Cannabis vs Coffee: The Science Behind the Ultimate Extraction

Regardless of the particular coffee roast or cannabis strain, the science of extraction underlies the true essence of these plants and their extracted products.

Your favorite coffee or expresso. The warm balance of the roast. The sweet and fruity notes. The robust and toasty finish. These traits come from a balance of oils, fruit acids, sugars, and aromatics, something you may have pondered after a sipping a cup or two. Chances are you’ve given less thought about where these qualities originate and how they find their way into your cup.

Extraction is the process that provides access to these qualities and compounds, through grinding the coffee bean, solubilizing in water, and separating the extract. Whether filtered coffee, French press, or espresso, all methods for brewing involve the central process of extraction. Each brewing method requires a consistent and ideal size of grind, ranging from coarse to super fine, and each extraction method calls for uniform coffee particles in order to deliver the unique characteristics of the brew.

One could think of cannabis or hemp concentrates in a similar light. Whether ethanol, butane, or supercritical CO2 extraction, the goals of these extraction techniques are the same – to gain access and harvest compounds and qualities of the plant. Each biomass processing method demands an ideal grind or milling output. And the success of each extraction method depends on controlled particle size, which translates to the value of the product for both the producer and the consumer.

Regardless of the particular coffee roast or the specific cannabis strain, there is a science to extraction that underlies the true essence of these plants and their extracted products. Dr. Markus Roggen, in collaboration with FRITSCH MILLING & SIZING, INC, recently explored the parameters behind cannabis extraction, with particular focus on the impact of milling performance on yield, consistency, and overall quality.

The Science of Extraction: Yield, Consistency, Quality

Yield, the percentage of material that is harvested from the source, is an important component of extraction. The “strength” of coffee relates to the percentage of dissolved compounds in the extract. The strength and consistency of a brew has everything to do with achieving the appropriate yield and maintaining this ability in subsequent attempts. Failure to do so can result in product that is either too thin and weak or shows unwanted variability from one batch to the next.

Cannabis and hemp processors strive to maximize extraction yields and harvest as much soluble material as possible for subsequent processing. If the yield of the cannabis extract is too low, potency of cannabinoids, terpenes, and other desirable compounds is diminished. If batch consistency is low, the quality and the value of the extracted product is compromised.

The Impact of Milling on Cannabinoid and Terpene Recovery

In their work, Dr. Roggen, Blake Grauerholz, and colleagues first set out to study the impact of particle size and consistency of the starting material on recovery yields of cannabinoids and terpenes.

In a first set of experiments, a homogenous mixture of whole plant material was ground into multiple samples ranging from 1 mm to 10 mm using a FRITSCH PULVERISETTE “P19” Milling System (shown on the right). In parallel, a mixed particle size sample produced using a food processor as well as an un-ground sample were analyzed. The RPM of the milling system was also varied during testing, in order to determine if there was any thermal degradation of compounds resulting from increased rotor speed. Lab testing was performed on pre- and post-milled material to determine recovery yields of terpenes and cannabinoids.

Results indicated that recovery yields of cannabinoids and terpenes increased as the size of the milled particles decreased. Furthermore, milling RPM of the P19 had minimal effects on decarboxylation or thermal degradation of compounds. This is consistent with the engineering and operational functionality of this device and the focus on heat load and temperature mitigation.

The Impact of Milling on Extraction Efficiency

The act of coffee grinding provides access to internal compounds within the cavities of the beans. The resulting exposure of increased surface area within the beans promotes extraction of the compounds. The size and the consistency of the coffee grinds, as well as the duration and precision of the process, have significant bearing on the success of extraction. Smaller size particles slow down the flow of water and increase contact time between the grinds and the water. Higher particle consistency results in better integrity of the extraction vessel, less channeling, and other effects. Whether pour over, flow, or pressurized extraction, the extraction efficiency is paramount in attaining that perfect cup of brew.

A further set of experiments by Dr. Roggen’s group focused on the impacts of particle size and consistency on cannabis extraction efficiency. A select range of particle sizes (2 mm, 6 mm, and 10 mm, along with controls) were used for CO2 extraction under typical production parameters. The effects of milling were determined by analysis of cannabis oil yield and composition.

Results indicated that finer, more uniform particle sizes provided better precision in extraction. Furthermore, smaller particle sizes resulted in higher quality and purity of cannabinoid fractions in the extracted product. Un-ground samples, on the other hand, offered minimal precision and demonstrated greatly reduced extraction yields compared with milled samples.

Espresso beans are typically ground to a fine consistency and packed tightly for extraction. Rapid extraction with hot, pressurized water gives rise to a highly concentrated, strong “shot” of coffee. In theory a tight, uniform particle size distribution should allow more cannabis material to be packed in an extraction column. This is turn should lead to increases in extraction yield.

To test this, the output of the PULVERISETTE P19 milling system was examined, and the particle size distribution was measured using the FRITSCH ANALYSETTE 22 Laser Particle Size Analyzer (shown on the right). Results showed a sharp peak at 1 mm, with minimal secondary peaks, indicative of a tight size distribution.

Further investigations of milled and un-milled cannabis within the extractor vessel demonstrated that indeed the packing density has a significant effect on total recovery.

The Impact of Milling on Quality

Additional factors can affect the overall quality of the extracted product. These include the ability to adjust or fine-tune milling in order to achieve the most desirable extraction yield and compound profile every time. In cannabis, this ability must be coupled with maintaining the chemical profile of cannabinoids, terpenes, and other valuable compounds, regardless of the type of starting material.

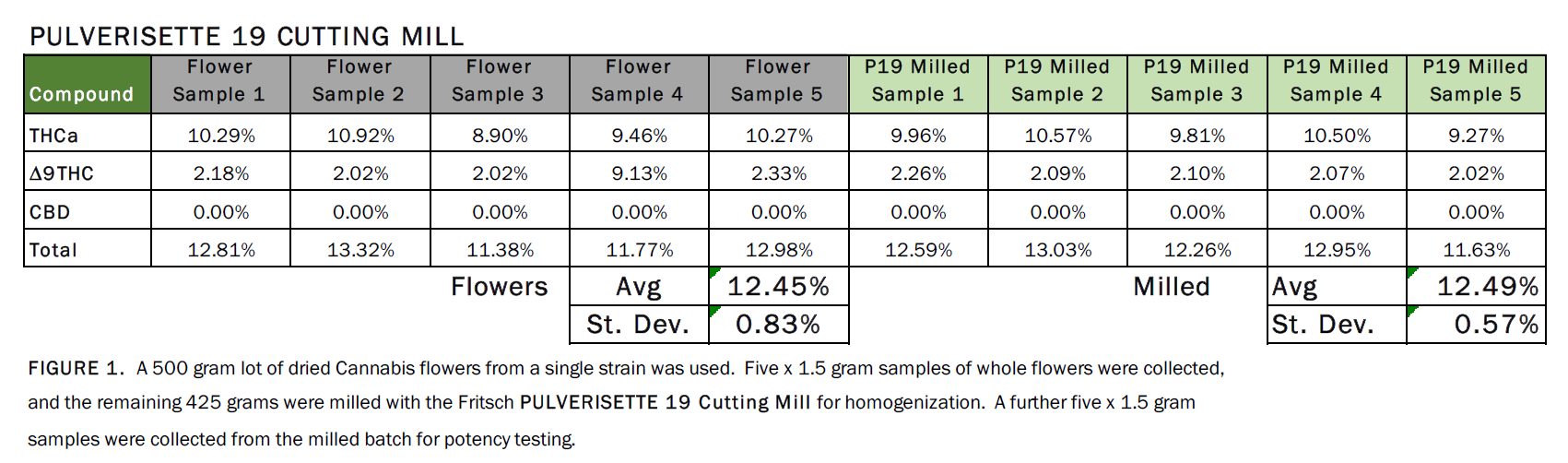

Extensive testing of whole flower versus the PULVERISETTE 19 milling system output, showed no significant differences in compound recovery of THCa, ∆9THC, and CBD in repeated analyses (Figure 1). These data illustrate batch to batch consistency and integrity of the chemical profile through use of this Precision Milling System.

Summary

Just as coffee extraction can be tuned to produce that perfect cup of brew, cannabis extraction processes can be optimized to maximize yields and ensure the integrity and quality of the product.

The body of research described above can be summarized with the following conclusions:

- Precision milling can produce the right particle size and a tight size distribution for optimal extraction yields.

- Process milling with the P19 does not significantly alter the integrity of the components nor the compound profile of the cannabis material.

- Use of the P19 promotes extraction efficiency while preventing capture of undesirable contaminants.

- The ability to control multiple parameters through the use of a device such as the PULVERISETTE 19 Precision Milling System enables processing of high-quality product suitable for a range of valuable downstream applications.

So, there you have it. Extraction is only as efficient as the quality and consistency of the starting material. In the case of cannabis, high-performance, precision milling makes all the difference. Now, back to that enticing cup of CBD infused coffee.

View a related Application Note on this research

Visit FRITSCH for more information